The original version of this story was published BikeRUmor,

Riders keep going fast and hard, which means that suspension has to be better and better to control and provide traction that needs top enduro racers. And the better they are New thorns and dampors Are, Fox flipped his thinking to see if they could make a single crown fork that performs like a double crown.

It turns out, they can. The all-new Fox Podium fork is an inverted single crown fork, and it is for the enduro bike.

Why the reverse?

Fox has three parameters that they focus on: control, comfort and traction. With reverse design, it gave them new ways to detect this balance.

The project did not begin with the idea of making an inverted fork. The initial goals were reducing friction and giving riders as hard as they could probably do with more confidence. Somebody suggested that an inverted design had the ability to dramatically reduce friction, especially when loaded.

Therefore, he tested a prototype on his two-axis test rigs, and the data proved the concept. He then made a prototype. They were heavy and big, but once a examiner caught it, they would not give it back.

And when they knew that they were on something: the project got a green light.

Weight vs friction

Some riders and products will perform a little to save weight. But more and more, riders are ready to add some grams to get better performance. From the high-pivot bike to the tire insert with Idler Puli, if it means to finish the race or ride the squares without any problem, or to hit the squares hard and sharp, then the full weight is not as good as it used to go.

So, Fox focused on performance, and especially on reducing friction. If you think that means the fork is super rigid and rigid, then you are Partially Correct.

Hard, but not too harsh

In front, the fork is Very Harsh. Because if you reduce friction with binding and bending forces, you can improve the dampors.

Why? Because friction, briefly, is a form of soaking in it that it slows down the fork movement. The problem with friction is that you cannot control it like you can do it with a sponge.

But by twisting, he left a little room. Yes, Crown and Beef 47 mm prevent the upper tube fork from twisting or bending during hard cornering, but they are not just spots that control the steering response … and this is where the axle comes.

A 15 mm axle was not quite rigid – even a completely solid. So the podium uses 20 × 110 boost through axle.

He tested a lot of axles, starting with three separate alloy versions. All the riders chose rigid, so Fox felt that it was worth testing some stifers.

Eventually, he switched to steel, and until the riders said too much, made him a stifer. They retreated slightly and landed in the sweet place, which gave the thorns the quality of a magical ride.

Shrubby appointment

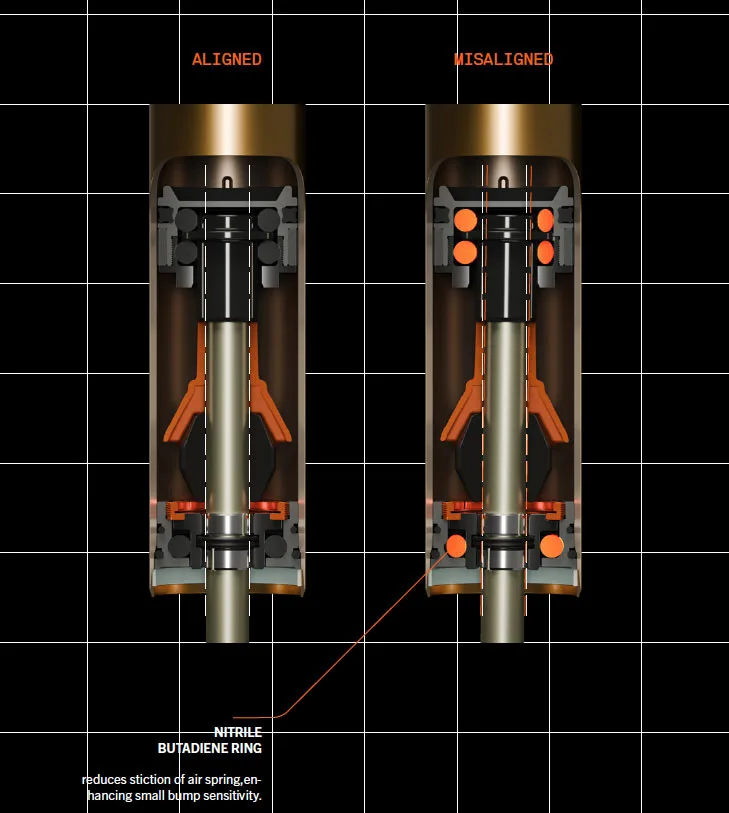

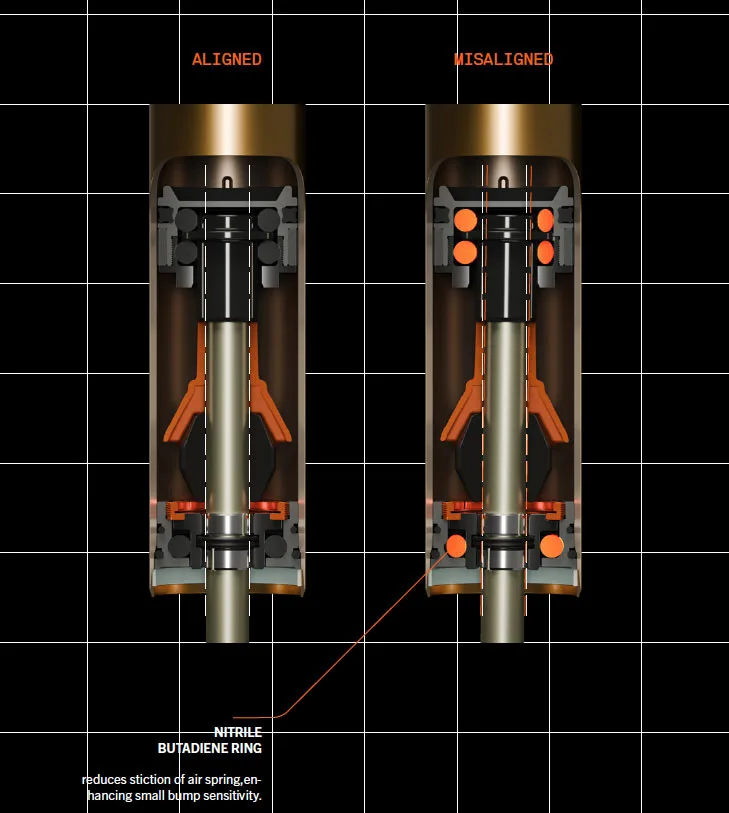

To reduce friction, hardness helps, but he also saw bush overlap, shrubbed placements and the oils he used for lubrication. He was already happy with his bush sizeBut compared to a specific fork, like 38, there were bushes opportunities Placement Will be better.

The dropout is designed to obtain Axle as a stanchian as close as possible, making it close to the lower bush sitting at the bottom of the apps.

Then, they moved the upper bush up further, leading to a distance from 120 mm to 174 mm, more than 38 32% growth, and 200 mm-trogue fox foose 7% more than 40 DH fork. Also in addition to the bushes, they are better that they break the Stanchian, but the reverse design offered another surprising advantage.

On a traditional fork, the distance from the axle to the bush never changes, so the load on the lower bush remains the same.

But on an inverted fork, such as axle becomes close to the lower bush during compression, the leverage force occurs on that bush ReduceSo it really becomes smooth because you go deep into travel. So much so that he had to re-designs the soaking on the X2 high-speed compression circuit for this fork.

The podium has a grip X2 dumper, but is extended exclusively with compression and rebound dumping for this fork.

In addition, the upper bush is fixed inside the chassis, so it is not a “trombone” shrub that slides with the stanchian. While a sliding design would have increased the bush overlap distance as a fork compressed, Fox says that the benefits were not enough to justify the additional complexity of the design, and it would require thick-wall tubes, so it adds weight.

For better performance, the real driver was creating a distance from Axal to less than the bush as low as possible.

Weight, oil, air springs, etc.

Weight was not the highest priority, but was not ignored. Taking what he learned from the liberal design of last year’s new 32 SC, he used that process to adapt the crown for both weight and hardness.

The Fox 38 is light, originally with the same axle-to-crown height, but the podium is stifer and smooth. And because the podium is upside down, there is less than 38 unsafe mass, it can react to more quickly (and recover).

Inverted design means that the seal between uppers and stanchions is constantly bathed in oil – thanks to gravity. This means better seal lubrication for smooth performance. Angeld grooves in the upper bush pass through oil to maintain fluids moving throughout the chassis.

Podium uses the latest glidcore air spring of Fox, which is debuted New 36 thorns earlier this year. The design uses flexible dumps between the shrubs of the air spring shaft, which allows the flex along with a fork instead of tying the shaft, no matter how difficult you do to pursue it smoothly.

The spring of the air is filled from the bottom, but there is a tube that goes inside the spring of the air so that when you fill it, the air enters the chamber above the lubricating oil, thus stopping from backfilling in any tube and in your shock pump. Let the bleeders at the top cap give you depression to compensate for height and temperature changes.

Fox says that the podium has the same service interval as their regular forks, and they say it is even easier to do because you can leave only one side at once.

Fox podium model, pricing and glasses

Podium comes in two versions:

- factory: Carbon Stanchian Guard, Kashima-Left Stanchian

- Demonstration class: Plastic Injection-Molded Guard, Black anodized Stanchian

The performance elite model is only for OEM imagination. For aftermarket, only the factory version is available in retail – here are the major glasses:

- Crown diameter: 58 mm and 68 mm options

- Wheel size: 29 ″

- travel: 170 mm and 160 mm options

- Upper legs: 47 mm diameter

- Stachian: 36 mm diameter

- Dumper: Grip x2

- Sponge Control: HSC – LSC – HSR – LSR

- Axle: 20 x 110 mm boost

- Rake: 44 mm

- Steer: 1.5 thinner

- Low tube finishes: Kashima

- Bypass channel: No (unnecessary due to reverse design)

- Bleeders: Yes

- Floating Axle: Yes

- Rotor Size: 200 mm direct post mount, 230 mm maximum

- Mud Guard Mount: Fox Mud Guard Fall available 2025

- Air Spring: Float evol glidecore

- Starting weight: 2,695g

Both versions have a fully anodized finish … there is no paint, which helps to save a little weight. And they are working on a crown-mounted fender. Podium MSRP watches at a price of $ 2,000.

Downhill version? cross country?

Fox developed podiums for Enduro Racesses and Hardcore all-mutetan riders. At the moment, he did not mention any plan to create a long travel version for downhill racing … but they are always working on the luggage. What about taking this design to XC?

“I can’t confirm or deny future product designs that are working on Fox,” said VP Bill Brown of Engineering for Mountain Bike Products. “But we will have a difficult time to lose weight to appeal to the XC crowd.”

Why not go to 180 mm? Because none of his pro rasors were using anything above the 170 mm journey, they stopped to keep it as possible as possible.